When most people think about an aircraft hangar, they imagine towering planes, sophisticated maintenance equipment, and the bustling energy of aviation professionals hustling from one task to the next. But behind that airborne excitement is something far more down-to-earth—literally. The floor beneath all that activity is a critical player in the safety, efficiency, and overall success of any aviation operation. And yet, flooring is often overlooked until problems arise, whether it’s a crack forming under immense weight, a stain that won’t come out, or a dangerously slippery surface.

If you’ve been relying on a standard concrete floor and wondering why it doesn’t seem to keep pace with the high demands of your hangar, you’re not alone. In this guide, we’re going to explore why conventional floors sometimes struggle in aviation settings and how Swisstrax can transform your hangar from the ground up. Not only will we dig into the specific challenges of hangar flooring, but we’ll also shed light on how Swisstrax meets and exceeds those challenges, often with minimal downtime and a surprisingly manageable learning curve. By the end, you’ll see why Swisstrax is more than a “nice-to-have.” It’s a must-have for any serious aviation operation.

Why Hangar Flooring Deserves Your Undivided Attention

Beyond a Simple Slab: The Unique Demands of Aviation

Aircraft hangars are unlike any other industrial or commercial space. Sure, they share some similarities with warehouses or large workshops, but the stakes are often higher and the environment more specialized. Think about it: airplanes, helicopters, and jets weigh thousands upon thousands of kilograms. They bring a whole host of fluids and chemicals—fuel, oil, hydraulic fluids—into contact with your floor. And then there’s the daily foot traffic of mechanics, engineers, cleaning crews, and administrative staff. Each step, each movement of machinery, adds a level of stress on your floor that ordinary surfaces just aren’t prepared to handle.

If we consider the day-to-day rhythm of an aircraft hangar, it’s a constant cycle of movement and maintenance. Planes come in from flights where they might have picked up moisture, contaminants, or even small amounts of salt from runway de-icing. As soon as they enter the hangar, they bring these substances onto the floor. Mechanics may be working with lubricants or degreasers, and spills are inevitable. Meanwhile, large vehicles such as tugs and tractors frequently roam around, adding even more strain.

A run-of-the-mill concrete floor in these conditions can deteriorate quickly, forming cracks or absorbing chemical spills that lead to permanent stains—and sometimes even bigger structural problems down the line. And that’s without even touching on issues like worker comfort, cleanliness, and aesthetics. So if you’ve been scratching your head over recurring floor repairs or safety concerns, now you know that it’s not just you. It’s the nature of the beast.

So unlike a conventional warehouse or a regular garage, an aircraft hangar must accommodate:

Enormous Weight Loads

Modern aircraft weigh thousands (if not hundreds of thousands) of kilograms. It’s not like parking a car in your driveway—these planes and jets need a floor that won’t buckle, crack, or warp under immense stress.Constant Chemical Exposure

Aviation fuel, de-icing fluid, hydraulic fluids, engine oils—the list of chemicals in regular contact with hangar floors goes on and on. A typical day in an aircraft maintenance facility can see spills of various sorts. If your floor absorbs these chemicals, you could be looking at serious damage or, worse yet, dangerous slick spots.Need for Worker Safety

Pilots, mechanics, engineers, cleaning crews—many professionals are on their feet for hours on end. Slippery floors, uneven surfaces, or cracks can spell disaster in a busy environment where everyone relies on stable footing.

The Real Cost of Subpar Flooring

We’ve all heard the saying “You get what you pay for,” but in the context of hangar flooring, you might end up paying a lot more in the long run if you settle for something subpar. It’s not just about the upfront installation costs. A floor that isn’t specifically designed for aviation use can present a mountain of hidden expenses:

- Frequent Repairs and Downtime: Hairline cracks can quickly turn into safety hazards when they propagate under heavy loads. Repair work often means halting or limiting hangar operations—a costly prospect if you rely on tight schedules.

- Increased Risk of Accidents: A slick surface or uneven flooring can cause employees to slip, trip, or fall, leading to potential injuries and, in the worst cases, legal or insurance complications.

- Poor Impressions on Clients and Partners: If you deal with private jets or executive travel, the last thing you want is a floor riddled with stains, cracks, or mismatched patches that scream “second-rate.” Image matters, especially in aviation, where safety and professionalism are paramount.

A substandard floor can become a financial drain, a productivity roadblock, and even a reputational pitfall. That’s why the question is not whether you should invest in quality flooring, but which solution offers the best balance of durability, versatility, and cost-effectiveness.

Why Concrete Falls Flat—And How Swisstrax Soars

The Drawbacks of Traditional Concrete

Concrete is a staple of industrial building, a sort of “default setting” for large floors that must withstand substantial load. It’s not without its merits—especially if you’re on a budget or you want a quick, standardized solution. However, in the intense environment of an aircraft hangar, concrete’s weaknesses become more apparent:

- Cracking Under Weight: Over time, even high-quality concrete can develop cracks under repeated stress. Every time an aircraft rolls in or out, the concrete absorbs impact forces. Eventually, this leads to small fractures that grow wider.

- Porous Surface: Concrete naturally has tiny pores that can absorb fluids. That might be okay for a simple warehouse, but in a hangar where chemicals and oils frequently spill, this porosity is a recipe for stubborn stains and potential chemical degradation.

- Thermal Sensitivity: Extreme temperature shifts, like hot summers and cold winters, can cause concrete to expand and contract. These shifts accelerate cracking and make the surface more brittle over time.

- Maintenance-Heavy: From sealing and polishing to patching cracks and filling holes, a concrete floor might require frequent TLC to remain safe and visually acceptable. Each of those maintenance activities can disrupt workflow and add to the long-term cost.

Concrete’s “industrial toughness” is sometimes a bit of an illusion in an aviation setting. When confronted with the intense weight and chemical exposure that hangars present, it frequently ends up falling short—both literally and metaphorically.

How Swisstrax Steps In as the Hero

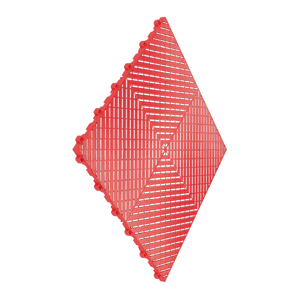

Swisstrax, by contrast, is a modular flooring system built from high-performance polymers that have been rigorously tested for resistance to weight, chemicals, and general wear and tear. Unlike concrete, which is a single, monolithic slab, Swisstrax tiles interlock to form a continuous surface. Picture it as a high-tech puzzle that covers your entire hangar, only this puzzle can withstand the landing gear of a massive plane or the corrosive effects of engine fluids.

Swisstrax wasn’t plucked from some random garage flooring idea. It’s engineered for tough, high-traffic, and chemical-heavy environments. The design inherently addresses many of the issues that plague concrete. Because the tiles lock together, stress is distributed evenly across the surface, preventing any single spot from taking all the load. And thanks to special surface textures, slip resistance is built right in, reducing the odds of workplace accidents. If a tile ever does sustain damage—maybe from an unusually hard impact—you can replace a single square rather than ripping up an entire floor section.

If you’re frustrated with the recurring issues of concrete (or any other standard flooring option), Swisstrax offers a breath of fresh air: a system specifically designed to thrive in exactly the type of environment you’re running.

Diving Deeper: The Key Benefits of Swisstrax for Aircraft Hangars

Durability and Weight Capacity

When an airplane parks inside your hangar, the landing gear transfers enormous weight directly onto the floor. Even smaller planes and private jets can tip the scales at thousands of kilograms. Swisstrax tiles are molded from high-quality polypropylene (among other robust materials, depending on the style), giving them an impressive load capacity that can handle an airplane’s heft without cracking or distorting.

In practical terms, this durability translates to fewer headaches and minimal disruptions. You’re not going to walk in one morning to discover a freshly formed crater or a sprawling crack that renders part of your hangar unsafe. Swisstrax is built for the job, day in and day out.

Chemical and Fluid Resistance

One of the biggest nightmares for traditional floors is the ease with which aviation fluids can seep in and wreak havoc. From jet fuel to specialized lubricants, these liquids can stain surfaces, degrade materials, or create dangerously slick spots. Swisstrax turns this common problem on its head. The non-porous nature of the tiles ensures spills remain on the surface, where they can be wiped up with minimal fuss.

This aspect is a huge perk for long-term floor maintenance. Instead of expensive cleaning protocols or repeated floor treatments, you can often handle spill cleanup with simple, readily available cleaning supplies. That alone can save countless hours—and a fair bit of money—over the life of your flooring.

Quick and Easy Installation

There’s a sort of universal dread around flooring installation because people imagine jackhammers, long cure times, and dust everywhere. That’s not the case with Swisstrax. Each tile snaps together via a clever interlocking mechanism, which means:

- Minimal Tools: Often, you’ll only need your own body weight to lock tiles in place.

- No Specialized Adhesives: Swisstrax doesn’t need messy glues or grouts.

- Fast Turnaround: Many hangar managers find they can transform large sections of floor in a fraction of the time it would take to lay or pour a new surface.

Also, if you have to rearrange or expand your hangar’s layout later, you can remove and reposition tiles as needed. Traditional floors can’t do that—once concrete is in place, it’s there for good, unless you shell out for demolition work.

Enhanced Worker Safety and Comfort

Aircraft mechanics often work long shifts, sometimes bending over or kneeling on hard floors for hours on end. By offering a slightly more forgiving surface than concrete, Swisstrax can help reduce fatigue and potential joint or back problems. The slip-resistant textures built into many Swisstrax styles also prevent accidental falls—an especially vital consideration when you’re dealing with heavy tools, high-value equipment, and flammable fluids.

For many hangar managers, the comfort factor is a somewhat unexpected (but very welcome) bonus. It’s not often that employees rave about how their feet and legs feel after a day in the hangar, but with Swisstrax, you might just hear that conversation.

A Polished Appearance That Boosts Credibility

Hangars that see visitors—clients, partners, or investors—need to leave a positive impression. Think of your floor as the “stage” on which all your aircraft and operations perform. If that stage is chipped, stained, or visibly uneven, it diminishes the aura of professionalism you’d ideally project. In contrast, Swisstrax offers a clean, modern look that showcases your aircraft in the best possible light. You can even choose from multiple colors or patterns, demarcate specific zones, or integrate branding elements directly into the floor design.

Real-Life Considerations for Installation and Maintenance

Preparing Your Existing Floor

While Swisstrax does not require you to tear up your existing floor, a little prep work can make installation smoother and yield better results. You’ll want to ensure the subfloor is relatively level, free of large debris, and mostly clean. Hairline cracks in concrete aren’t a deal-breaker—the tiles will bridge those gaps—but significant holes or large elevation changes might need patching or leveling.

It’s usually a good idea to sweep, vacuum, or pressure-wash the surface before laying your first tile. This basic cleaning step helps remove dust or dirt that might interfere with the interlocking mechanisms or keep the tiles from lying flush.

Snap, Lock, and Go

Once your subfloor is ready, the actual installation process is surprisingly intuitive. You typically start at one corner of the hangar and work your way across, snapping each tile into place as you go. If you need to trim any tiles around odd corners or obstacles, you can usually do it with a jigsaw or a sturdy utility knife. The entire floor can come together in a fraction of the time it takes to pour, level, and cure concrete.

Because it’s a modular system, you’re not locked into your first layout if you later decide you want to reorganize. Tiles can be popped up and reinstalled in new configurations with minimal hassle. This flexibility is a game-changer if your hangar frequently changes to accommodate different sizes or types of aircraft.

Keeping It Clean for the Long Haul

Maintaining Swisstrax is straightforward. Daily or weekly sweeps can remove surface grit, and a mild detergent with water is often enough to tackle tougher spills or stains. Should a significant spill occur—like a large fuel leak—you can lift out the affected tiles, clean underneath, and replace them right back in place once everything is dry.

That’s a stark contrast to dealing with stained, cracked concrete that might require professional cleaning or patching. With Swisstrax, you can handle most maintenance tasks in-house, quickly, and without specialized equipment.

Installing Swisstrax: The How-To Breakdown

Pre-Installation Prep

You don’t need a ton of specialized training or tools to install Swisstrax, but a bit of planning goes a long way. Before diving in:

- Clean the Subfloor: Remove debris, old paint flakes, or any oily residue that might affect the tiles’ performance.

- Ensure Level Surfaces: While Swisstrax can handle some unevenness, overly large bumps or cracks in the subfloor should be repaired or leveled out first.

- Measure Twice, Cut Once: Sketch out your hangar floor, noting where you might need to trim tiles to fit corners or around fixed equipment. A simple utility knife or jigsaw can handle these cuts easily.

The Installation Process

- Snap and Go: Position the first tile in a corner and work your way out. Align the looped edges toward the open area; pressing down on the tile edges snaps them together. It’s that simple!

- Mind the Edges: If you need to trim tiles near doors or walls, do so as you progress. This saves you from having to go back and rework completed areas.

- Allow Expansion Gaps: Leave a slight gap along walls or barriers to accommodate any thermal expansion. This prevents buckling during hot weather.

Post-Installation Tips

- Immediate Use: One of the great perks of Swisstrax is that you can start using it right after installation. No waiting for adhesives to cure!

- Periodic Checks: While the tiles are tough, a quick monthly or quarterly inspection helps you stay ahead of any minor issues. Keep an eye on high-traffic areas to ensure no edges have lifted or tabs have broken.

- Easy Config Changes: If your hangar layout changes—maybe you’ve added new equipment or reconfigured your storage area—just pop out the tiles in that section, rearrange, and snap them back. Flexibility is the name of the game.

Maximizing Safety and Compliance with Swisstrax

Why Slip Resistance Matters

Aircraft hangars aren’t always climate-controlled paradises. During winter, you might have de-icing fluid around; during summer, high humidity could lead to moisture build-up. Add in occasional spills, and you have a recipe for slip-and-fall accidents if your floor isn’t up to par.

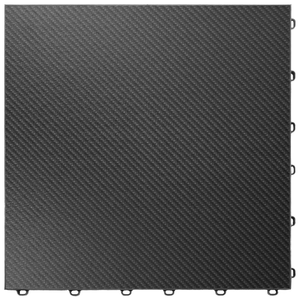

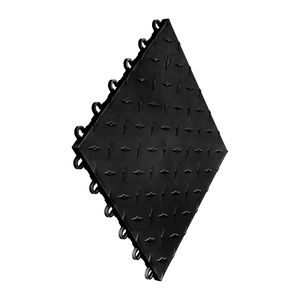

- Textured Surfaces: Swisstrax tiles often feature ribbed or diamond-plate textures to maximize traction. Think of it like wearing shoes with a great tread pattern—it’s all about the grip.

- Drainage Channels: Some tile designs have channels that allow liquids to drain away or evaporate quickly, keeping the surface relatively dry.

Fire Resistance and Other Safety Codes

Many jurisdictions have stringent fire safety and building code requirements, especially for spaces housing aircraft and fuel. Swisstrax tiles are often manufactured to meet or exceed these standards, but it’s always a good idea to confirm the specifics for your region.

- Flame Spread Ratings: Certain polymer formulations can resist ignition and slow flame spread. Checking these specs helps you ensure regulatory compliance.

- Local Codes: Always cross-reference local building codes or consult with a professional to ensure that your floor solution is fully compliant. The last thing you want is a surprise visit from inspectors forcing you to redo your floor.

Cost Considerations and ROI

The Bigger Picture: Value vs. Price

A common concern when upgrading to a specialized flooring system is cost. Sure, Swisstrax might have a higher upfront price tag than simply pouring concrete. But if you look beyond the initial sticker price:

- Reduced Maintenance Costs: No more frequent repairs, sealing, or patchwork. Over a 5- to 10-year span, those savings alone can justify the investment.

- Less Downtime: Time is money. A one-day or weekend installation (or reconfiguration) beats the lengthy process of prepping, pouring, and curing new concrete.

- Longer Lifespan: Because Swisstrax doesn’t degrade quickly under chemical exposure and heavy loads, you won’t be replacing it as often, if ever, compared to traditional solutions.

Energy Savings? You Bet!

It’s an often-overlooked benefit, but the slightly insulated nature of Swisstrax tiles can help regulate temperatures. Concrete is known for being cold and unforgiving—especially in colder climates. By adding a layer of Swisstrax, you may find the hangar feels warmer underfoot, potentially reducing some heating needs in the winter. Every little bit helps, especially if you’re in a place that sees sub-zero temperatures.

Real-World Success Stories: Swisstrax in Action

A High-End Private Jet Hangar

Imagine a private jet hangar that doubles as a showpiece for luxury travel clients. The hangar owner wanted a professional aesthetic that matched the elegance of the aircraft it housed. Swisstrax provided a polished, customizable flooring system with color-coordinated walkways and parking zones. Visitors are consistently wowed by the spotless, modern look—and the staff love how easy it is to keep the floor shining.

Maintenance Heavy Commercial Hangar

On the other end of the spectrum, a busy commercial hangar with a high turnover of different planes day and night needed a durable solution. Constant exposure to jet fuel, oils, and other chemicals was eating away at the old concrete floor. Upgrading to Swisstrax allowed for:

- Instant Chemical Cleanup: No more permanent staining or corroded areas.

- Quicker Turnarounds: Damaged tiles could be swapped out in minutes.

- Greater Worker Morale: A clean, safe environment has kept downtime to a minimum, and the crew can focus on what they do best—keeping planes flight-ready.

Balancing Form and Function: Design Tips

Color-Coding Your Space

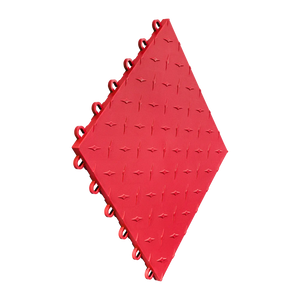

One of the coolest aspects of Swisstrax is its range of colors. This isn’t just about eye candy; strategic color use can enhance workflow and safety. For instance:

- Red Zones: Mark off hazardous areas or restricted zones.

- Green Lanes: Delineate safe walkways or indicate paths for equipment transport.

- Contrast Designs: Use bold patterns or contrasting borders around important areas, such as maintenance pits or tool storage zones, to catch attention at a glance.

Emphasizing Your Brand

Have a company logo or specific brand colors? Incorporate them right into the floor design. This can be especially appealing if clients or visitors frequent your hangar. Your floor can become a conversation piece, leaving a memorable impression as people admire a logo or pattern embedded in the tiling.

Tailoring Tile Styles to Different Tasks

Swisstrax isn’t a one-size-fits-all solution. They offer various tile surfaces—ribbed, solid, textured, etc. Consider mixing styles:

- Ribbed for Drainage: Place ribbed tiles in areas prone to fluid spills or near entrances where water or snow might be tracked in.

- Smooth or Diamond-Plate for Comfort: Reserve these in areas where staff spend the most time standing or kneeling.

Maintaining and Troubleshooting Your Swisstrax Floor

Regular Cleaning Routine

Keeping your Swisstrax floor looking spick-and-span isn’t rocket science:

- Daily or Weekly Sweeping: Depending on traffic, a quick sweep or vacuum will help remove dust, grit, and other loose debris.

- Mopping or Light Detergent Wash: For more intensive cleaning sessions, a gentle detergent solution works wonders. Power washers can also be used but follow manufacturer guidelines to avoid excessive pressure on the tiles.

- Chemical Spill Cleanup: Because Swisstrax repels most fluids, spilled fuel or oil rarely penetrates. Wipe it up promptly and perform a quick rinse if needed.

Damage Control and Quick Fixes

One of Swisstrax’s major selling points is the ease of repair. If you notice a cracked or damaged tile:

- Snap Out, Snap In: Use a flat tool to gently lift out the damaged tile. Align the new tile and snap it into place.

- Edge Repairs: If the interlocking tabs themselves are damaged, you might need to trim off the compromised section. But given the modular nature, you’ll rarely have to replace a large area.

- Preventative Care: Encourage staff to report any floor damage immediately. Quick fixes keep the situation from escalating, maintaining a safe environment.

Building Trust in the Aviation Sector

When it comes to aviation, trust is everything. Whether you’re flying a single-prop plane for weekend getaways or operating a fleet of commercial jets, you can’t cut corners—especially not on something as critical as your hangar floor.

Swisstrax has made its name by partnering with car enthusiasts, professional race teams, and yes, even aviation experts who demand the absolute best. Over years of development, Swisstrax has demonstrated that it can stand up to the toughest conditions. Its reputation in motorsports and industrial settings isn’t just hype—it’s built on a proven track record that aligns well with Google’s emphasis on expertise and trust.

By choosing a flooring solution like Swisstrax, you’re aligning with a brand that has shown credibility across multiple industries. That credibility is an asset when you need to show business partners, inspectors, or even local authorities that your hangar meets high safety and operational standards.

Demonstrating Experience and Authoritativeness

Nobody wants to be the guinea pig for an untested product, especially in aviation. Swisstrax has the advantage of visible case studies and testimonials from industries as demanding as motorsports, aviation, manufacturing, and more. Organizations that prioritize precision and reliability have endorsed the product, lending it an authoritative seal of approval.

When inspectors or potential clients walk onto a Swisstrax floor, they recognize that you’ve chosen a solution respected in multiple high-stakes arenas. This immediate recognition can go a long way toward establishing trust and authority in your operation.

A Special Note for Finland: Swisstrax via Tallitkuntoon

If your hangar is located in Finland—or you’re planning to set one up there—the good news is that Swisstrax is available through Tallitkuntoon. Tallitkuntoon specializes in delivering and advising on Swisstrax solutions that cater to local conditions, including those harsh Finnish winters.

Why does this local availability matter? For one, you can get hands-on support for your flooring project. Whether you have questions about subfloor prep or want guidance on tile choices, Tallitkuntoon offers expertise tailored to Finnish regulations and climates. That means one less hurdle in ensuring your new floor stands strong against snow, ice, and temperature swings.

From small private aircraft hangars in remote locations to larger commercial facilities, Tallitkuntoon can help you make informed decisions about design layouts, color schemes, and specialized tile types. It’s not just about buying a product; it’s about getting a flooring system that’s perfectly suited to your specific situation and operational demands.

Are There Any Downsides? Addressing Common Concerns

Initial Cost vs. Long-Term ROI

Let’s not dance around the issue: Swisstrax can have a higher initial purchase price than a bare-bones concrete pour. However, that’s only one part of the equation. If you consider the long-term benefits—reduced maintenance, minimal downtime, extended lifespan, and improved safety—the return on investment often favors Swisstrax. Additionally, the ability to swap out damaged tiles (rather than redoing entire sections) can save a fortune in repair bills over the years.

Aesthetic Choices and Personal Preference

Some hangar owners may prefer a plain concrete aesthetic for that rugged, industrial feel. While that’s a valid preference, it’s worth remembering that Swisstrax offers a range of colors and finishes, from understated grays to vibrant patterns. You can certainly create a look that’s subtle and professional, or you can opt for something more eye-catching. The important thing is that you’re not forced into a monochrome, utilitarian appearance if you’d like a bit of visual flair.

Learning Curve for Installation

Though Swisstrax installation is simpler than pouring concrete, it’s not as intuitive as rolling out a carpet. There’s a mild learning curve, especially when it comes to cutting tiles around odd shapes or ensuring the entire floor aligns neatly in large hangars. That said, once you get the hang of the interlocking system, the process moves quickly. Many first-time installers report that they’re surprised by how smoothly it all goes.

How to Plan Your Swisstrax Hangar Upgrade

Step 1: Assess Your Existing Space

Take a thorough inventory of your current flooring condition. Are there large cracks or unlevel sections that need addressing? How is the drainage? Does water or snow melt from aircraft get trapped anywhere? Understanding these factors will help you gauge what, if any, subfloor preparations are needed before you roll out the first tile.

Step 2: Map Out the Layout

Before purchasing tiles, sketch a layout of your hangar. Mark off zones for aircraft, storage, mechanical work, and foot traffic. Swisstrax offers different tile styles—some better for high-moisture areas, others for maximizing comfort—so identify where each style might be most beneficial. This is also a great time to consider color-coding or branding opportunities.

Step 3: Consult with Experts (If Needed)

Even though you can often install Swisstrax on your own, getting advice from professionals can save time and trouble, especially in complex hangars. If you’re in Finland, Tallitkuntoon can provide personalized recommendations based on your hangar’s size, typical aircraft load, and chemical exposure level. If you’re elsewhere, seeking out a local Swisstrax distributor or an experienced contractor can also be invaluable.

Step 4: Schedule Your Installation

Minimizing downtime in an aircraft hangar is crucial. Plan your installation for a time when operations are naturally slower, or when you can temporarily shift activities to a different area. Because Swisstrax tiles can be laid so quickly, you’ll likely be back to full operation much sooner than if you were redoing the concrete.

Step 5: Ongoing Care and Monitoring

Once your new floor is in place, set a schedule for basic cleaning. Keep an eye out for any damaged or scuffed tiles, so you can replace them right away. Proactive maintenance will keep your floor looking pristine and safe for everyone.

Elevating Safety and Professionalism with One Smart Move

We’ve journeyed through the challenges unique to aircraft hangars—immense weight loads, chemical exposure, and the relentless cycle of maintenance and repairs. We’ve also seen how traditional concrete floors often fall short under these demanding conditions, leading to costly downtime and repeated fix-ups that never seem to resolve the core issues. Now, imagine a floor that transforms those headaches into manageable tasks: easy spill cleanups, tile replacements that take minutes rather than days, and a surface engineered to handle the stress of heavy aviation equipment without cracking.

That’s the essence of Swisstrax. It’s not just a fancy name or a trendy product. It’s a well-tested, performance-oriented flooring system that tackles hangar challenges head-on. From the chemical resistance that keeps spills from becoming permanent stains to the modular design that allows speedy repairs, Swisstrax has been winning over aviation professionals for good reason.

There’s also a strong argument to be made about how it immediately upgrades the look and feel of your hangar. Appearances matter more than we often like to admit, particularly when you’re trying to assure stakeholders, clients, or even employees that you prioritize safety, innovation, and quality. A Swisstrax floor announces that you’re not cutting corners.

The Finnish Connection—and Moving Forward

If you’re reading this from the Nordics, you might have additional considerations like harsh winters or the frequent need to clear snow and ice off planes. That’s where Tallitkuntoon steps in with localized expertise. Rather than navigating these flooring challenges alone, you can lean on professionals who understand what you’re up against—from frigid temperatures to specific Finnish regulations.

In any aviation setting, though, the big takeaway is the same: high-performance hangar flooring pays off both immediately and over the long term. It’s an investment in safety, efficiency, and reputation. By choosing Swisstrax, you’re opting for a solution that has a proven track record, can adapt to your evolving needs, and doesn’t trap you in a cycle of constant repairs. You’ll feel the difference every time you step onto that floor—or tow a massive airplane across it without worrying about leaving cracks in your wake.

Final Thoughts—Ready to Take Your Hangar to New Heights?

Think of your hangar floor as the runway for all the critical work that keeps aircraft safe and operational. A compromised runway in the open skies would be unthinkable, right? So why settle for a compromised floor in your hangar? Upgrading to Swisstrax is like giving your aircraft a smooth, durable, and future-proof landing spot, right where you need it most.

From rapid installation to easy maintenance, from chemical spills to massive weight loads, Swisstrax covers it all—quite literally. That’s why mechanics, engineers, and aviation business owners around the globe are retiring their old concrete floors in favor of this versatile, resilient, and visually striking solution. And if you happen to be in Finland, Tallitkuntoon is right there to make the journey effortless, ensuring you get a floor that stands up to Nordic challenges without breaking a sweat.

So, ask yourself: Do you want a floor that merely exists, or do you want one that actually enhances and safeguards your operation? If your answer leans toward the latter, it might be time to leave the concrete age behind and embrace the future of aircraft hangar flooring. With Swisstrax, you’ll have peace of mind knowing your ground operations are as robust and reliable as the aircraft you service. And that, my friend, is the definition of a solid investment. Safe landings—and enjoy your elevated new hangar floor!