Understanding the Concept of Modular Interlocking Flooring

A Puzzle for Your Floor

When people say “modular interlocking flooring,” the first mental image you might conjure up is a giant puzzle sprawled across your floor. Honestly, that’s not far from the truth! Modular interlocking flooring consists of individual tiles (or squares, sometimes rectangles) that snap, click, or lock together along the edges. It’s akin to putting together a jigsaw puzzle where each piece is designed to fit seamlessly with its neighbor.

However, unlike a standard cardboard puzzle, these flooring tiles aren’t meant to be taken apart after a fun afternoon of puzzle-solving. Once installed, they stay put, creating a sturdy yet flexible surface. The beauty of this design is that you don’t need specialized adhesives to hold the tiles together. And if you ever need to replace a single tile—maybe one gets damaged or you simply fancy a change of color—you can pop out that specific piece without disturbing the entire floor. It’s a simple, modular approach to a durable and adaptable flooring system.

Snap, Click, and Lock

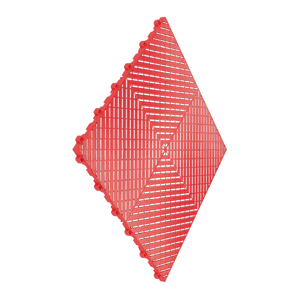

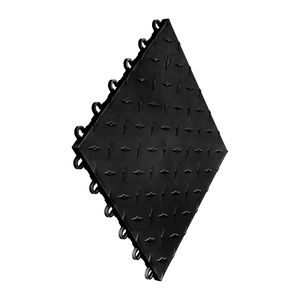

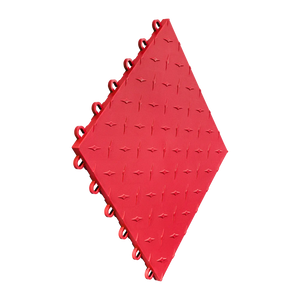

The term “interlocking” basically describes the mechanism by which these tiles attach to each other. Think of Lego bricks: each block has studs on top and corresponding tubes underneath, allowing them to attach so snugly that you can pick up an entire Lego structure by grabbing a single brick. Modular interlocking flooring uses a similar principle—but for adult-sized floor tiles. Every tile has a series of tabs or loops on one side and a corresponding set of slots or “receivers” on the adjacent edges. When you press them together, the tabs slide into the slots, locking the tiles in place.

This quick and straightforward system makes installation a breeze. You don’t need to be a professional contractor, nor do you need a small army of specialized tools. If you’ve got a rubber mallet or sometimes just your own body weight, you can typically snap the tiles together in a matter of hours, turning an empty—or even occupied—floor space into something functional and stylish.

Creating a Unified Surface

One of the most remarkable aspects of modular interlocking flooring is how the tiles form a solid, unified surface once they’re locked in place. You might still see the outlines of individual tiles, but there is no gapping or spacing issue if the system is installed correctly. It’s like taking multiple smaller pieces and forging a single, cohesive puzzle that covers every inch of your floor.

This unity not only looks neat but also helps with stability. The interlocking mechanism essentially distributes weight and stress across multiple tiles, which can help the floor handle heavier loads and daily wear and tear. This collective strength is part of what makes modular interlocking flooring so versatile, but before we tumble down that rabbit hole, let’s keep our focus on the “what” rather than the “why or where” of these tiles.

How Does Modular Interlocking Flooring Work?

The Anatomy of a Tile

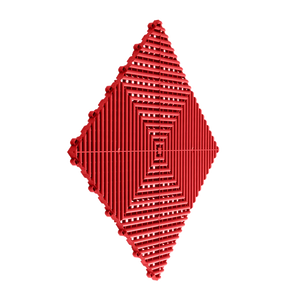

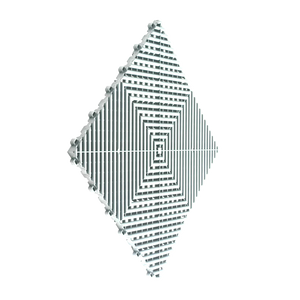

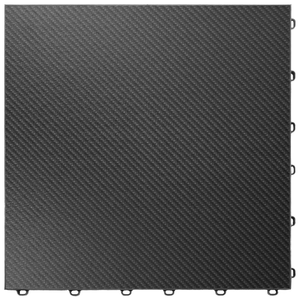

A typical modular interlocking floor tile isn’t just a flat square of plastic. Instead, it’s often carefully engineered with different layers and structural patterns. Some have raised tread designs that allow water or debris to drain underneath. Others might feature a smooth top layer ideal for showing off logos or patterns. And then there’s the underside, which usually includes a network of supports or “feet” to give the tile its strength and help it remain slightly elevated from the ground.

This raised design can be a lifesaver in environments where moisture is a concern. Since the tile is not glued down to the underlying floor, air can circulate underneath. In some tile designs, water can even flow beneath the floor instead of pooling on the surface, preventing slippery conditions. Imagine a busy garage or workshop—spills happen, but with many modular interlocking floors, cleanup is much easier because liquids don’t always sit on top like a puddle in a parking lot.

Easy Installation Philosophy

Modular interlocking flooring is all about DIY-friendliness. Most systems are designed so that anyone with a pair of hands and maybe a utility knife or rubber mallet can put the pieces together. The tiles come in standardized dimensions—often one square foot, but other sizes exist—so planning your layout is relatively straightforward. You measure your floor’s total area, figure out how many tiles you’ll need, and perhaps keep a few spares for good measure.

Then comes the installation day. Many times, you can install the tiles right over your existing surface without major prep work, though you’ll want to ensure it’s clean and free of large debris. From there, it’s “puzzle time.” You start at one corner of the room, align the first tile, and then snap the second tile into place. One by one, you’ll fill out the area, making cuts around obstacles if needed. If you can operate a tape measure and cut carefully when necessary, you’ll breeze through the process. By the end of the installation, you’ll have a new floor that’s level, sturdy, and infinitely more attractive than whatever was there before.

Durability and Longevity

Once installed, each tile supports and strengthens the neighboring tiles. This interlocking grip is what keeps the entire floor from shifting when cars drive over it, heavy machines roll across it, or kids dance on it to their favorite tunes. While exact lifespans vary based on the material and environment, modular interlocking floors are known to be long-lasting. And the best part? If a single tile does wear out or gets damaged for any reason, you can replace it individually without redoing the whole space. It’s like swapping out a single puzzle piece—no big deal!

Materials Used in Modular Interlocking Flooring

Plastic Variants

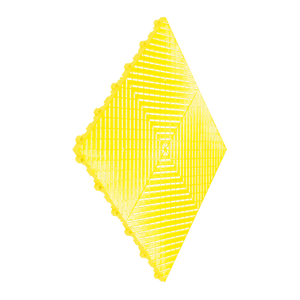

When most people picture modular interlocking flooring, they’re likely imagining some form of high-impact plastic. Plastic tiles are common because they’re durable, lightweight, resistant to corrosion, and relatively easy to produce in a rainbow of colors. Common plastic materials include polypropylene, a type of thermoplastic that strikes a good balance between flexibility and rigidity. Polypropylene tiles often feature textured surfaces that add grip, which is handy in areas prone to spills or moisture.

But not all plastics are created equal. Some manufacturers might choose denser PVC for extra sturdiness. Others might use specialized compounds that incorporate rubber-like elements for better sound absorption or anti-fatigue properties. It all depends on the intended usage—though we’ll stay focused on the definition aspect rather than diving into all the “pros” of each material.

Rubber-Based Tiles

Rubber-based interlocking floors are another popular choice, especially in environments where cushioning or shock absorption is critical, like home gyms or play areas. Unlike plastic, rubber gives you a more flexible, slightly softer surface. This can be excellent for absorbing impacts, whether from dropped weights or the pitter-patter of tiny feet. Rubber interlocking tiles also offer noise reduction, which might help keep the peace if you’re living in a shared building or do a lot of activity in your workspace.

Hybrid Constructions

You might come across flooring solutions that blend different materials to achieve a specific goal. For instance, some tiles have a plastic base for structural stability with a rubber top layer for comfort and grip. These hybrid constructions can be an elegant solution if you need the best of both worlds—sturdy support combined with a comfortable walking surface. While they’re not as common as purely plastic or purely rubber tiles, they showcase the versatility of the modular interlocking concept. Essentially, if a manufacturer can design tiles that lock together, they can experiment with different materials to fine-tune the floor’s performance.

Breaking Down the Installation and Maintenance Process

Before You Begin: Prepping the Surface

Although modular interlocking tiles can often be installed directly over your existing floor, it pays to spend a little time on prep. After all, even puzzle pieces fit best on a clean, flat table. Sweep or vacuum your floor to remove dust and debris. In some cases, you might want to mop or scrub away any stubborn stains. If the underlying floor has large cracks or major uneven sections, you may want to repair or level them out to ensure your new floor tiles will sit flush. Think of it as giving your puzzle a pristine workspace so that every piece snaps effortlessly into place.

Step-by-Step Installation

When you’re ready to dive in, it’s smart to figure out the best corner of the room to start. Typically, you’ll begin in the left corner furthest from the entryway, so you can work your way across in rows or columns. Lay the first tile, then snap the next tile into place. You’ll typically hear a satisfying click or pop when the tabs and slots align correctly—like pressing the final edge on a piece of Tupperware. With each new tile, you create a continuous “extension” of your puzzle.

If you encounter an area where you need to fit the tile around, say, a post or a built-in cabinet, you can cut the tile to size. Many plastic tiles are easy to trim with a saw or even heavy-duty shears, while rubber tiles might require a bit more elbow grease or a specialized blade. The key is to take your time, measure carefully, and double-check before making any cuts. Once you’ve conquered those tricky corners, everything else usually proceeds smoothly.

Keeping It Clean

Maintenance is another area where modular interlocking flooring shines. Spills and dirt don’t penetrate beneath the tiles because, in most designs, they either stay on top or drip through to the space below if the surface is perforated. For solid-top or rubber tiles, a quick sweep or mop typically does the trick. If you’re dealing with liquid that has seeped underneath, many tile systems allow you to lift a portion of the floor to clean beneath it. It’s almost like flipping up a puzzle piece to reveal something that slipped under—handy if you want to keep the subfloor in pristine condition.

Regular sweeping or vacuuming keeps loose debris at bay. If you need a deeper clean, you can use mild detergents without worrying about damaging the tiles.

Bringing It All Together: Why the Definition Matters

More Than a Simple Floor

At its core, modular interlocking flooring is an ingenious system: individual tiles equipped with a puzzle-like mechanism that allows them to fit tightly together. No messy adhesives, no permanent alterations to your space—just a modular solution that can expand, contract, or even move if your needs evolve. Think of it as a chameleon for your floor, ready to adapt to your requirements, whether you’re revamping your garage, setting up a commercial workshop, or sprucing up a basement room.

Understanding the basic definition of modular interlocking flooring is crucial if you’re exploring new floor solutions. You’ll want to know what materials are used, how the system snaps together, and what kind of prep work is involved before committing to the project. Even though we’re deliberately sidestepping detailed benefits and comparisons here, you can start to see why homeowners, business owners, and facility managers are drawn to this flexible approach.

Why Finland Loves Swisstrax from Tallitkuntoon

If you happen to be in Finland—or you just like to keep tabs on global flooring trends—you might be interested to know that Swisstrax is available from my company Tallitkuntoon. You can find us online at www.tallitkuntoon.fi. Swisstrax offers a range of high-quality modular interlocking flooring tiles that embody everything we’ve discussed: ease of installation, sturdy materials, and a visually appealing design. While brands can differ in terms of color choices, texture options, and performance levels, Swisstrax stands out for its commitment to top-notch manufacturing and creative tile patterns. And if you’re seeking that puzzle-like transformation for your Finnish garage, workshop, or commercial setting, Tallitkuntoon is here to help you make it a reality!

Frequently Asked “Non-FAQs”

Will Modular Interlocking Flooring Make My Life Easier?

You might be quietly asking yourself whether modular interlocking flooring is just a gimmick. After all, how can something that essentially clicks into place be strong enough to support vehicles or heavy machinery? The short answer lies in the design: each tile is engineered to share the load across multiple connection points. It’s the same reason why a well-built bridge distributes weight across multiple beams and supports. Don’t let the puzzle analogy fool you—this is serious engineering hidden behind a deceptively simple installation process.

Isn’t It Just an Overglorified Mat?

Some folks believe modular interlocking flooring is basically a fancy mat that you roll out on your floor. But a mat is usually a single piece, and if you need more coverage, you might buy a larger one or lay multiple mats side by side, risking bunching or shifting. By contrast, interlocking tiles create a unified surface with edges that lock together, preventing slippage and ensuring an even transition from tile to tile. So, while you might be able to throw a mat on your garage floor and call it a day, it’s not quite in the same league as a custom-fitted interlocking tile system designed for consistent performance.

How Does It Handle Temperature Changes?

Temperature can affect the expansion and contraction of certain materials—particularly plastic. The good news is that modular interlocking floors account for this. Many tile designs include small gaps or built-in expansions in the interlocking mechanism to accommodate minor shifts due to temperature fluctuations. So, if you live in a place like Finland, where winters can be frosty and summers can get surprisingly warm, your interlocking tiles are built to handle those seasonal mood swings.

Final Thoughts: A Puzzle Worth Solving

Modular interlocking flooring is like the friend who always comes prepared: easy to get along with, flexible when you need changes, and there for the long haul. By demystifying what it is and how it works, you’re already halfway to deciding whether it’s a good fit for your next flooring project—whatever that might be. From the puzzle-like mechanism that makes installation a cinch, to the variety of materials that tailor each tile to a specific environment, modular interlocking flooring proves itself to be more than just another trend.

Ultimately, knowing the definition helps you see the bigger picture. It’s about the synergy between design and function, between ease of installation and reliable performance. And if you ever find yourself eyeing that drab garage floor or daydreaming about a slick new surface, now you know exactly what’s behind the magic of modular interlocking flooring. It’s the Lego for grown-ups, the puzzle you never outgrow—only this time, the final masterpiece stays on the ground, reminding you daily of your brilliant flooring choice.

So the next time you hear someone talking about “snap-together tiles,” you can confidently chime in with your new-found knowledge. You’ll know it’s not just a fancy mat or a short-lived fad, but a robust, ever-evolving flooring system whose puzzle pieces fit snugly into the story of modern, adaptable design. And if you’re reading this in Finland, don’t forget that you can find high-quality Swisstrax tiles from Tallitkuntoon at www.tallitkuntoon.fi. Because once you’re ready to leap into the world of modular interlocking flooring, it never hurts to have a trusted source on speed dial.