Have you ever walked onto a floor that clicked together like puzzle pieces, each tile neatly locking in with the next? That, my friend, is modular flooring in a nutshell. It’s a concept that brings together convenience, versatility, and a design-friendly approach—all without stepping into the realm of “benefits” or “types.” We’re here to talk about what modular flooring is, how it’s conceptualized, and the broader framework that makes it such a unique element in modern spaces. In this article, we’ll break down the building blocks (quite literally) of modular flooring, focusing on Swisstrax as a prime example of how the idea has evolved into a sophisticated solution. So, grab a seat and get ready for a deep dive into this fascinating subject. Let’s roll out the metaphorical red carpet—or should I say, the interlocking tile mat?

The Foundations of Modular Flooring

A Concept Rooted in Simplicity

At its core, modular flooring is exactly what it sounds like: a floor made up of modules or individual units. These units—often tiles—are designed to fit together in a precise manner, almost like a jigsaw puzzle with perfectly shaped pieces. Each tile is a self-contained block that can click or snap into the neighboring tile, forming a stable and cohesive surface.

If you’re picturing old-school building blocks or maybe even those interlocking toy bricks from childhood, you’re not too far off. The foundational principle is all about ease of assembly and consistent alignment, allowing people to create a stable walking surface without needing complex adhesives or specialized tools. There’s a beauty in that simplicity: it taps into a universal understanding of how pieces lock together to form something greater than the sum of their parts.

From Ancient Paths to Modern Tiles

While modular flooring as we know it today might seem like a modern invention, the basic idea of using discrete units to form a walking surface is as old as civilization itself. Think about ancient stone pathways built out of uniform blocks or intricate mosaics composed of small, interlocking pieces. These early examples may not have been called “modular flooring,” but the principle remains the same: smaller pieces arranged to create a larger, functional area.

Over centuries, we’ve added technology, refined materials, and developed sophisticated manufacturing methods. Fast-forward to contemporary times, and you’ll find that many industries have embraced modularity, from automotive engineering to interior design. We see it in tile systems for bathrooms, kitchens, showrooms, and more. With the rise of modern polymers and production techniques, today’s modular flooring is leaps and bounds ahead of hand-chiseled cobblestones. It’s lighter, more resilient, and easier to integrate into various environments. But fundamentally, the heart of modular flooring hasn’t changed: separate pieces, working together, to form a cohesive whole.

Understanding the Mechanics Behind Modular Flooring

Interlocking Technology 101

One of the hallmarks of modern modular flooring is interlocking technology. Picture two puzzle pieces meeting at their edges: each piece has a protrusion that fits into a corresponding indentation on the other. This concept ensures that once the tiles or modules are joined, they hold each other securely in place. Think of it like a firm handshake—neither side wants to let go easily.

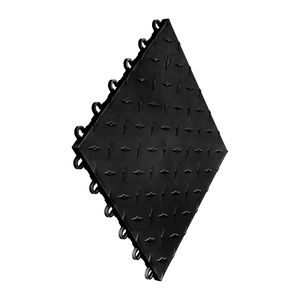

This interlocking can be achieved in various ways. Some tiles use “male and female” connectors, where one side features a small loop or peg and the other side a corresponding slot or hole. Others may rely on a snap system that clicks into place with an audible sound of satisfaction—kind of like that click when you buckle your seatbelt. The mechanics might differ among manufacturers, but the outcome is the same: a floor that feels stable and solid underfoot.

Materials That Bring Durability and Flexibility

While modular flooring might be made from a variety of materials—ranging from soft foam to rigid metal—one popular choice is polypropylene, a type of tough plastic that resists wear, tear, and many forms of damage. It can handle hefty loads, extreme temperatures, and even chemical exposure. Another common option is PVC (polyvinyl chloride), which offers a different balance of flexibility and strength.

Swisstrax, for example, is known for using high-quality materials that strike a balance between sturdiness and adaptability. They manufacture tiles that won’t succumb to slight shifts in the ground beneath them—like an old wooden plank might—while also providing just enough give to make it comfortable for walking or standing for extended periods.

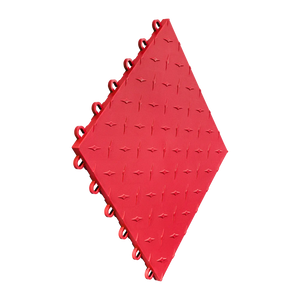

The question you might be asking is, “Why plastic?” Well, this type of polymer is notable for its light weight and relative ease of fabrication. It’s also inherently water-resistant, making it suitable for places where moisture might be present, such as garages or outdoor patios. Add in color options, textured surfaces, and patterns, and you’ve got the kind of aesthetic variety that appeals to homeowners, designers, and even folks in industrial settings.

The Swisstrax Identity: A Snapshot of Excellence

A Brand Synonymous with Modular Innovation

Let’s zero in on Swisstrax for a moment, because it’s hard to talk about modular flooring without mentioning them. The brand stands out for combining practical engineering with an eye for design, leading to a collection of modular flooring products that are recognized globally. From residential garages to commercial showrooms, Swisstrax tiles have made a name for themselves in large part due to their distinctive look and feel.

Swisstrax’s approach is rooted in precision manufacturing. Each tile is crafted with meticulous attention to detail, aiming for exact measurements so that each piece consistently fits with the next—no wobbly edges or awkward gaps. This emphasis on uniformity means you can lay tile after tile, row after row, and the result is a cohesive expanse that feels like one continuous surface.

How Swisstrax Became the Gold Standard

Now, “gold standard” might sound like a flashy label, but many consider Swisstrax to be at or near the top of the modular flooring industry. But what exactly catapulted them there? It’s a question of brand ethos and engineering know-how. The company focuses on innovation—constantly refining their tile designs, vent systems, locking mechanisms, and color palettes to stay relevant in a market where customers always want something fresh.

Swisstrax also pays close attention to quality control. Each tile typically goes through rigorous checks to ensure it meets standards for durability and precision. If a tile doesn’t click or snap together perfectly, that doesn’t just affect a single tile—it has the potential to disrupt the entire flooring layout. By prioritizing consistent manufacturing methods, Swisstrax ensures that every box of tiles you open has the same reliability as the last one you used.

And no, we’re not here to tout the advantages or cost savings. We’re simply laying out the reality: Swisstrax has earned a widespread reputation by emphasizing the “what” aspect of modular flooring—namely, creating meticulously crafted tiles that serve as the building blocks of countless floors around the world.

Where Modular Flooring Finds Its Home

Spaces That Embrace Modular Concepts

You might be surprised by how many places embrace modular flooring. Yes, there’s the quintessential garage scenario, but beyond that, you’ll find these interlocking tiles in gyms, showrooms, trade show booths, and even places like poolside areas or mudrooms. Essentially, anywhere that needs a practical, reliable surface that can handle the day-to-day foot traffic or occasional heavy-duty activity is a candidate for modular flooring.

But the question is: what sets these spaces apart? They often require flooring solutions that can be adapted or customized quickly. Whether it’s swapping out a damaged tile or changing the layout for a special event, the puzzle-piece nature of modular flooring makes it convenient for transformations. And while we could delve into the reasons and benefits behind that, we’re focused on the “what” side of the equation: a system that easily conforms to a wide variety of space configurations, be it a narrow hallway or an expansive hall.

The Growing Popularity in Modern Design

Have you ever noticed how design trends come and go? One season it’s all about open-concept living, the next, minimalism. Amid these shifting sands, modular flooring has carved out a stable niche in modern design, partly because of its chameleon-like ability to blend aesthetics with practicality. Architects and designers often rave about the creative possibilities—mixing and matching colors or patterns to achieve a unique vibe.

Even in the context of brand experiences, companies set up modular flooring at promotional events to create visually striking stages or walkways. Then, once the event is over, they can disassemble it and move on. This sort of plug-and-play flexibility speaks volumes about the “what” behind modular flooring: it’s a puzzle you can build, break down, and rebuild—no sweat, no fuss.

Stepping Into the Details: Composition and Design

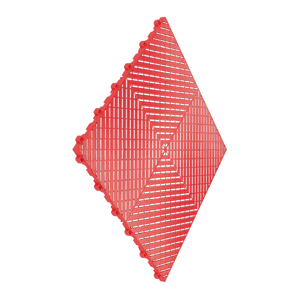

Anatomy of a Swisstrax Tile

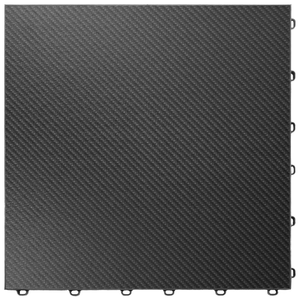

Let’s pop open the hood on a single Swisstrax tile to see what’s going on inside. Typically, a Swisstrax tile has a grid-like structure on top, which allows for certain functional elements (like airflow or moisture drainage) but also lends a unique, textured appearance. On the underside, you’ll find a lattice or rib system that reinforces the tile, distributing weight across the entire piece to enhance durability.

Each tile has connectors on its edges—some pointing outward, others inward—designed to align snugly with adjacent tiles. This uniform design is part of the reason why you don’t need a professional contractor to lay Swisstrax floors in many cases. If you can line up the edges and press down until you hear the click, you’re good to go.

The Role of Texture and Pattern

One aspect that often goes unnoticed is the top-layer design. In some modular flooring systems, the top might be completely smooth, while in others—like many Swisstrax options—it might resemble a vented or ribbed pattern. This is not only for aesthetics; the pattern can influence grip, drainage, and even how light interacts with the surface.

Imagine sunlight streaming through a window and dancing on a patterned floor. The interplay of light and shadow can create visually stunning effects, a subtle artistic flair that some people don’t expect from a floor that’s essentially made of plastic. This is where modular flooring crosses the line from purely functional to something that can be integrated into a broader design vision.

Why Modular Flooring Has a Universal Appeal

The straightforward “what” of modular flooring can be summed up in one word: adaptability. We’re dealing with a concept that’s meant to fit various spaces, design preferences, and operational demands. It’s like building with Lego bricks—one day you can create a castle, the next day a spaceship, using the same pieces. Sure, the analogy might feel whimsical, but the principle stands. Each tile is a potential building block for a new layout, a new pattern, a new environment.

A True Mix of Form and Function

When you walk into a room fitted with modular flooring—especially the kind that’s carefully designed by a brand like Swisstrax—it’s hard not to be struck by how clean and uniform the surface looks. Sometimes, you might catch yourself running a hand over the tile, marveling at its texture or how each segment aligns with the next. Yet, behind that aesthetically pleasing design lies a meticulously engineered structure intended to handle the wear and tear of daily life.

This duality—looks meeting durability—forms the backbone of modular flooring’s broad-based appeal. People often see it as an intersection of engineering and design, bridging that gap between raw practicality and creative flair. It’s a conversation starter, really: “Oh, what’s this floor made of? How does it fit together?” And that curiosity is exactly what makes it fascinating to so many.

Examining the Lifecycle of Modular Flooring

From Production to Deployment

So how does modular flooring move from raw materials to the finished product in your home or workspace? Typically, it starts in a manufacturing facility that molds or extrudes materials like polypropylene into specific tile shapes. These facilities use high-pressure injection molding machines, where liquid plastic is forced into a mold that defines the tile’s final geometry.

Once the tiles have cooled and hardened, they’re inspected to ensure the connectors, edges, and surface patterns match the required specifications. If all is good, they’re packaged and shipped out. When they arrive at your doorstep (or your warehouse, or job site), each tile is ready to slot into the next without the need for glues or adhesives. It’s almost like each piece has been pre-approved to join the giant family of tiles that will form your new floor.

Maintenance and Long-Term Care

Again, without delving into benefits or disadvantages, it’s worth mentioning how modular flooring is structured for a potentially long lifecycle. The general idea is that if one tile is damaged, you can pop it out and replace it. This is a direct result of its “modular” nature. You’re not locked into permanently glued-down materials, which might require a total overhaul if something goes wrong.

It’s a system engineered to be both modular and replaceable, ensuring that the overall surface remains cohesive while individual tiles can be attended to if necessary. This is part of “what” modular flooring is: a puzzle of discrete pieces that collectively create a unified canvas, all while allowing for changes and tweaks over time.

Debunking Common Misconceptions About Modular Flooring

“It’s Just Plastic, Right?”

One of the biggest misconceptions about modular flooring is that it’s all basically the same—cheap plastic squares that might not hold up well. But in reality, the manufacturing techniques, material quality, and overall design intricacies can vary wildly. Swisstrax, for instance, utilizes a specialized compound of polypropylene or other robust polymers that are engineered for longevity and performance. So while, yes, at a glance it may look like a plastic tile, the “engine” under the hood is far more refined than many might assume.

“Isn’t Installation Too Complicated?”

Another myth floating around is that because it’s a specialized system, installation must be tricky or require professional contractors. But if you’ve ever had the patience to put together a decent puzzle, you already have the basic skillset. The only difference is that here, the puzzle pieces are uniform, and they won’t keep you guessing as to which edge lines up where. It’s more straightforward than assembling a piece of furniture from a set of instructions—fewer bits, fewer steps, fewer headaches.

The Ethical and Sustainable Edge

Manufacturing with a Conscience

In today’s world, we can’t talk about what something is without at least touching on where it fits within the broader context of sustainability. Many modular flooring manufacturers, Swisstrax included, are actively seeking to reduce their environmental impact. While the details of these efforts often involve marketing statements about recycled materials or energy-efficient production lines, the fundamental “what” is that modern modular flooring often tries to align with more responsible manufacturing processes.

Even the concept of modularity itself might lend a hand here. When you can replace a single tile instead of junking an entire floor, you cut down on waste. That’s a tangible, structural aspect of what modular flooring is: a system built to facilitate partial rather than total replacements.

Meeting Evolving Consumer Expectations

As consumers become more eco-conscious, they’re asking tough questions: “Where do these tiles come from? Is the material recyclable? How long does the floor last before it ends up in a landfill?” These questions push manufacturers to refine not just their product lines but also their messaging and core business practices.

While we’re sticking to the “what” of modular flooring, it’s critical to recognize that modern tile systems increasingly speak to a global push for ethical production and minimized waste. We live in an era where these considerations aren’t just nice add-ons—they’re becoming integral to a product’s identity and acceptance in the marketplace.

The Ever-Evolving Landscape of Modular Flooring

Technological Advances on the Horizon

Imagine modular tiles embedded with smart sensors that track foot traffic or automatically adjust surface temperature. Or tiles that can change color under different lighting conditions. While these concepts might sound futuristic, the modular flooring industry is no stranger to innovation. Research and development teams constantly explore ways to push the boundaries of material science, engineering, and design.

We might one day step onto a tile that can harvest kinetic energy from our footsteps, powering LED accent lights around the floor’s perimeter. That scenario might still be a ways off, but the trajectory is clear: as technology moves forward, so does the potential of modular flooring systems.

Global Influences and Cultural Adaptations

Modular flooring isn’t a strictly Western or European phenomenon. It’s crossing borders, adapting to cultural needs and regional styles. For example, in areas with extreme climates—be it scorching heat or bone-chilling cold—manufacturers tailor their materials to withstand temperature fluctuations. In humid or flood-prone regions, they develop tiles with enhanced water resistance and drainage features.

This global expansion shapes what modular flooring is today—a truly international concept that must navigate diverse environments and tastes. As it does so, new designs and methodologies emerge, further enriching the modular flooring universe.

Bringing It All Together—A Modular Mosaic

Let’s pause for a moment and recap: What exactly is modular flooring? Think of it as a meticulously engineered system of interlocking tiles, often made from robust polymers, designed to create a stable, uniform, and customizable surface. It’s the puzzle you build to meet your floor’s unique shape and usage requirements, whether you’re outfitting a bustling car showroom, a cozy home garage, a sleek fitness studio, or a dynamic trade show booth.

Swisstrax stands out among the players in this space due to its precision crafting and constant drive for innovation. That doesn’t make it the only name in the game, but it does make it a prime example of how modular flooring has evolved from rudimentary blocks to sophisticated systems that capture the imagination and meet the demands of modern spaces.

At its heart, modular flooring is the physical manifestation of the idea that big things can be built from small, interlocking parts. It’s a testament to human ingenuity—taking a simple principle of connection and repetition and turning it into something that underpins commercial spaces, personal environments, and everything in between.

Swisstrax Product Availability in Finland

If modular flooring piques your interest and you’d like to implement it using Swisstrax tiles in Finland, be sure to check out www.tallitkuntoon.fi.

We are an official reseller of Swisstrax products in Finland and offer expert guidance along with a wide range of Swisstrax products. Through our services, you’ll find the perfect solutions for garages, storage areas, and any other spaces where you value easy installation, adaptability, and a striking look.

Conclusion: The Ties That Bind—Understanding Modular Flooring’s Core

Modular flooring could be likened to a jigsaw puzzle for grown-ups, or perhaps a building block set for the design-savvy. It’s an idea that merges artistry, engineering, and practicality in a neat, interlocking package. By focusing on the “what,” we see it for all it is: a structured flooring system composed of discrete pieces that fit together seamlessly, adaptable to countless layouts and aesthetics.

As you walk away from this article—metaphorically stepping off your newly assembled modular floor—remember that there’s a whole world of nuance behind each tile, from the manufacturing process to the global design trends that shape it. And if you ever find yourself standing on a Swisstrax floor, or any other brand’s modular system, you’ll know exactly what it is: a marvel of modular engineering, wrapped up in an approachable, puzzle-like form.

Just like that, you’ve taken your first deep dive into the realm of modular flooring—the concept, the construction, and the continually evolving nature of this fascinating system. While we’ve steered clear of explicit benefits or “why you should choose it” lists, the core idea remains undeniably captivating. It’s flooring that refuses to be just another surface underfoot; it’s a testament to flexibility, innovation, and an unwavering dedication to precision. So, next time someone asks, “What’s modular flooring?”—well, now you’ve got plenty to talk about.