Early Civilizations and the Concept of Interlocking Surfaces

Ancient Experiments in Flooring

It might seem surprising, but human beings have been searching for sturdy, practical, and decorative flooring solutions for thousands of years. Of course, when we think of ancient flooring, we picture stone slabs in Greek temples or the elaborate mosaic tiles of Roman villas. But the idea of making pieces “fit together” to create a smoother, more durable surface has roots that stretch even further back.

In prehistoric times, people primarily used natural materials—hard-packed earth, woven reeds, and even wooden planks—to provide comfort and insulation from the cold ground below. Over time, they realized that aligning or overlapping materials in certain patterns resulted in a more stable surface. Early humans likely noticed that interlacing reeds or arranging planks in a puzzle-like manner helped prevent shifting, slipping, or other annoyances. In a sense, these were the first baby steps toward what we might call an “interlocking system.”

Take, for example, ancient Mesopotamian civilizations that paved key buildings with fired clay bricks, ensuring each piece was carefully locked into place with mortar or bitumen. This wasn’t exactly “modular interlocking” as we know it, but it did lay a conceptual foundation—people began to understand that using smaller, uniformly shaped segments could lead to a more reliable and repairable surface than massive, singular slabs.

Transitioning to More Organized Floor Patterns

Fast-forward to the Greek and Roman eras, where engineers sought ways to create expansive, level surfaces that could endure the wear and tear of foot traffic, chariots, and livestock. The Romans, in particular, were masters of building. From their famed arches to their innovations in concrete, they explored various methods to make floors durable, beautiful, and at least somewhat modular. Elaborate mosaics made of tesserae (tiny square tiles) were hammered into mortar in intricate patterns. Although these tiles weren’t specifically made to “lock” together the way modern systems do, each piece was cut to fit snugly against its neighbors, creating a cohesive, continuous surface.

What’s fascinating is that these efforts weren’t just about aesthetics; they were about longevity, ease of repair, and functionality. If one part of the floor got damaged, you could remove the affected pieces and replace them without tearing out the entire surface. Sound familiar? That’s one of the major appeals of modern interlocking systems. And while the engineering might have been rudimentary by modern standards, the ancient world provided a vital stepping stone—literally—for everything that followed in flooring design.

The Industrial Era: Birth of Modern Interlocking Flooring

The Influence of Mass Production on Flooring

The Industrial Revolution in the 18th and 19th centuries ignited significant changes in manufacturing, architecture, and public infrastructure. Suddenly, methods for producing uniform, standardized parts took center stage, whether it was in making textiles, automobiles, or even building materials. Mass production drastically reduced costs and made it possible to explore new inventions that had previously been too expensive for the average business or home.

Concrete, steel, and metal framing became everyday staples in construction, which paved the way (pun intended) for new kinds of flooring solutions. Factories required surfaces that could handle heavy machinery, high foot traffic, spills, and all sorts of industrial abuse. Wooden floors or crudely finished concrete just weren’t cutting it anymore. Enter the concept of floor tiles that could be manufactured in large quantities with consistent dimensions and quality.

It was around this time that the idea of an interlocking tile began to germinate in the minds of engineers and entrepreneurs. If you could make uniform tiles that snapped or locked together without needing permanent adhesives, you could replace or move them with minimal effort. This would be a huge advantage in factories, where equipment sometimes needed relocating, or where damaged floor sections required quick repairs. Though the earliest attempts were pretty basic—often employing hooks, clips, or overlapping edges—the foundation was set for a design that would take off in the decades to come.

Early Twentieth-Century Innovations

As we rolled into the 20th century, the concept of modular floor systems gained more traction. The automotive industry, in particular, was a catalyst for such innovations. Auto production lines demanded robust floors that could sustain the weight of vehicles and machinery, while also offering flexibility to modify layouts on the fly. Companies started tinkering with materials like rubber and linoleum to create snap-together flooring solutions. Although these early systems still relied on adhesives more often than not, the notion of standardized, removable tiles was definitely making headway.

Meanwhile, the public’s fascination with the “jigsaw puzzle” concept found its way into various consumer products. People wanted easy assembly in everything from toys to household items. This cultural appetite for convenient, modular products blended perfectly with the growing interest in hassle-free flooring. During the mid-1900s, patents began popping up, describing “lock-together” floor tiles that utilized novel tongue-and-groove designs, which allowed for quick installation and stability without traditional glues or nails. Even though these solutions were not as seamless or efficient as modern systems, they signaled the dawning of a new era for flooring solutions.

Technological Breakthroughs and the Plastic Revolution

PVC and Polypropylene: Game-Changers for Flooring

While early versions of interlocking flooring could be made from rubber, wood composites, or even metal, the real turning point came when plastic production became widespread and cost-effective. World War II accelerated research and development in synthetic materials, including PVC (polyvinyl chloride) and polypropylene, which would later become mainstays in various types of interlocking floor tiles.

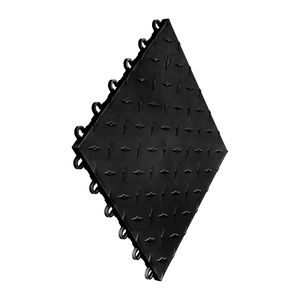

PVC, for instance, offered durability, water-resistance, and flexibility—features that lent themselves perfectly to flooring. Manufacturers found that PVC could be molded into precise shapes, complete with interlocking edges that would snap snugly together. Similarly, polypropylene proved its worth in creating rigid, strong tiles that could withstand significant weight and wear. The possibilities seemed endless: you could design different textures for traction, color variations for aesthetics, and even perforations to allow liquids to drain through the tile rather than pool on top. It was as if a door to infinite customization had swung wide open.

At this point, flooring designers and manufacturers began to realize they had stumbled upon something special: a modular system that could be quickly installed, handled heavy loads, resisted chemical damage, and didn’t require the same labor-intensive processes as traditional flooring methods. Consumers, from hobbyist car enthusiasts to large-scale industrial facility managers, were quick to latch onto the benefits of these newly developed interlocking tiles.

From Factories to Garages—Broadening the Adoption

During the late 20th century, the reputation of interlocking flooring extended beyond industrial settings into residential and recreational spaces. Home garages, gyms, and even outdoor patios started to adopt these solutions. Why? Because many homeowners were tired of dealing with cracked concrete, oil-stained driveways, or damp basements. An interlocking floor offered a quick facelift: snap the tiles together, trim them to fit around corners if necessary, and suddenly your garage or basement looked professional, neat, and incredibly functional.

This period also witnessed a surge in marketing efforts highlighting ease of installation. Ads would showcase smiling families unrolling or snapping together tiles over the weekend—no specialized tools or messy adhesives required. The sense of empowerment that came with installing your own floor without having to hire professionals struck a chord, and word spread quickly.

By the mid to late 1990s, many well-known home improvement stores began stocking boxes of interlocking floor tiles, making them more accessible than ever. From foam tiles designed for playrooms to heavy-duty rubber mats for weight rooms, the notion of jigsaw-like flooring tiles was taking over. The market was no longer limited to hardcore industrial or commercial use; it was very much in the mainstream.

Influential Brands and Global Growth

The Rise of Specialized Brands

As demand soared, the market opened up for specialized brands that focused on perfecting the interlocking tile concept. It was not uncommon to find brand names associated specifically with different materials—some excelled in PVC-based tiles designed for chemical-heavy environments, while others cornered the market in polypropylene tiles ideal for garages and workshops. Competing brands pushed each other to innovate, leading to improved locking mechanisms that were stronger and more seamless, as well as advanced surface textures that provided better grip or aesthetic appeal.

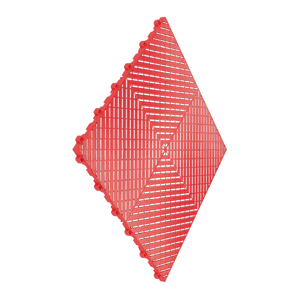

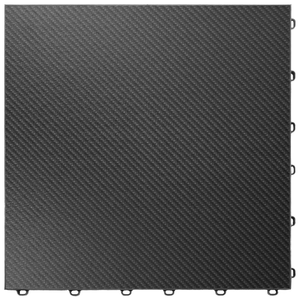

One notable brand in the interlocking flooring landscape is Swisstrax. Their tiles, known for durability and modular design, have found a home in countless garages, commercial spaces, and events worldwide. Manufacturers like Swisstrax have continually refined their technology, offering solutions with enhanced ventilation, easy drainage, and a snappy locking system that lays flat without warping. As the competition intensified, customers benefited from not only improved performance but also a broader range of design options to suit any preference—from bold colors to subtle, sleek finishes.

Interlocking Flooring Goes Global

With the rise of e-commerce and international shipping, these specialized flooring brands became more widely available worldwide. It wasn’t long before the variety of interlocking tiles grew astonishingly diverse, offering solutions for nearly every environment—be it an icy ski lodge, an aquatic facility, or a scorching-hot desert garage. Global growth also brought about interesting regional twists. In some parts of the world, the focus turned to anti-microbial properties due to warm, humid climates. Elsewhere, cold-resistant materials were developed for locations that endure harsh winters.

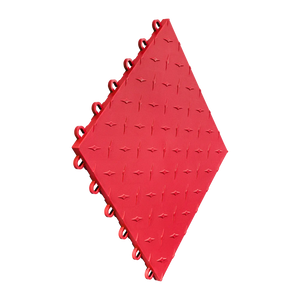

Over time, these interlocking tiles didn’t just stay limited to functional spaces. They started showing up in interior design magazines, a testament to their versatility and modern aesthetic. Designers began experimenting with using contrasting colors to create patterns or walkways within larger spaces, effectively merging practicality with artistic flair. This expansion into more decorative realms helped solidify modular interlocking flooring as a solution that transcended mere utility.

In Finland, for example, Swisstrax tiles are readily available through my company Tallitkuntoon, which you can find at www.tallitkuntoon.fi. That local availability has made it easier for Finnish customers to explore high-quality, versatile solutions for garages, workshops, and more—always a bonus when your flooring needs to withstand Scandinavian winters.

The Modern Landscape of Modular Interlocking Flooring

Cutting-Edge Materials and Designs

As we step into the 21st century, the technology behind interlocking tiles continues to race forward. Manufacturers aren’t just sticking to the tried-and-true PVC and polypropylene formulas; they’re introducing hybrid composites, recycled materials, and even tiles that integrate surface treatments to improve traction or reduce static electricity. For example, in electronics manufacturing facilities, you can find specialized anti-static tiles that protect sensitive equipment from electrostatic discharge. Meanwhile, in certain environments where slip-and-fall accidents are a real danger, tiles may come with aggressive tread patterns, offering a firm grip even when wet or dusty.

If you’re someone who appreciates a bit of style, the modern era has you covered. It’s no longer just about utilitarian grays and blacks. The wide array of colors, textures, and finishes means you can customize your floor to match a corporate brand identity or even create bold checkerboard patterns in your garage. Want a tile with a metallic sheen that catches the light and shows off your prized car? You can get that, too. There’s even a growing niche for tiles that mimic natural materials like wood or stone, offering a more traditional look with all the benefits of a synthetic interlocking system.

Additionally, installation mechanisms have become more user-friendly than ever. Many of today’s designs boast hidden interlocks that provide a nearly seamless appearance. This eliminates the puzzle-piece look that might deter some homeowners or architects. Combine that with simple cleaning routines—just a quick sweep, mop, or hose-down—and it’s easy to see why these floors keep gaining popularity.

Consumer Awareness and Environmental Considerations

It’s no secret that modern consumers care about sustainability. More and more people and organizations want building materials that leave a smaller carbon footprint, are easy to recycle, and promote healthier indoor environments. Recognizing this, manufacturers have begun to incorporate post-industrial and post-consumer recycled plastics into their products. Some even design their tiles so they can be disassembled and recycled at the end of their lifecycle, making the entire process more eco-friendly.

Such designs benefit not just the planet but also a company’s bottom line. If you can take up the floor tiles and reuse them in a new layout or a different facility altogether, you’re saving on material and labor costs. That reusability factor resonates with modern businesses seeking to reduce waste and maintain flexibility in ever-evolving industrial or commercial environments.

On the consumer side, an increased focus on environmental impact drives people to ask more questions: Where do these materials come from? How long will they last? Can they be recycled? Companies that address these concerns transparently tend to earn consumer trust and loyalty. This feedback loop of innovation and consumer demand pushes the evolution of interlocking flooring even further, ensuring that tomorrow’s tiles will be more efficient, sustainable, and appealing than ever before.

Looking Ahead: Future Trends in Modular Interlocking Flooring

Despite how far modular interlocking flooring has come, the journey is far from over. Emerging technologies hint at mind-boggling possibilities, such as tiles embedded with smart sensors to monitor foot traffic or structural stress. Imagine a warehouse floor that signals when a particular area is being overused or where spillage might have occurred—making it safer, more efficient, and easier to maintain. Or picture a home gym where the tiles track your movement, offering instant feedback on your workout session. These ideas might have seemed like science fiction decades ago, but they’re rapidly inching closer to reality.

The drive toward sustainability will likely continue to shape product innovation. Bioplastics, which derive from renewable sources like corn starch or sugarcane, are already under research and development. If they prove cost-effective and durable, we could see a new generation of biodegradable or compostable floor tiles that still meet rigorous performance standards. Even beyond environmental concerns, the push for healthier indoor air quality—by minimizing off-gassing and using non-toxic additives—will probably encourage new chemical formulations that maintain durability without compromising safety.

Moreover, the aesthetics of interlocking floors will keep evolving. Digital printing and improved molding techniques can replicate natural textures so convincingly that it might become hard to distinguish a polymer tile from authentic hardwood or marble. With custom design options, your garage floor could become a canvas for artistic expression or branding, turning a functional area into a statement piece.

Ultimately, interlocking flooring has proven it’s more than just a trend; it’s a flexible, scalable solution that adapts to technological advances and user needs. From humble beginnings in ancient civilizations to the cutting-edge systems we see today, these floors have always been about solving problems: durability, ease of installation, repairability, and visual appeal. And if history is any indication, the next chapters in this story will be just as exciting, filled with new materials, new designs, and new ways to make flooring an even more integral part of our everyday lives.

Final Thoughts on the Evolution of Interlocking Flooring

From ancient humans who pieced together reed mats to modern engineers crafting polymer tiles with hidden locks, the story of interlocking flooring is a testament to humanity’s love of simple, effective solutions. Each era brought its own twist—whether it was mortar-based mosaics in Rome or the sleek, snap-together tiles that line garages today. While we may not often pause to reflect on the ground beneath our feet, the evolution of modular interlocking flooring is a fascinating saga of creative engineering, material science, and collective problem-solving.

Looking around at today’s offerings, it’s clear we’re experiencing a golden age of modular flooring. And there’s never been a better time to explore what these systems can do for both industrial and personal spaces. The future promises even more innovation, blending sustainability with cutting-edge technology to make floors smarter, greener, and more versatile.

For those in Finland who want to experience the quality of interlocking flooring firsthand, Swisstrax tiles are available from Tallitkuntoon (official importer and dealer). You can explore all the options at www.tallitkuntoon.fi. Whether you’re looking to transform a chilly garage or set up a robust workspace in your basement, these modern, stylish tiles are part of a legacy that started ages ago with simple, clever ideas. After all, the best solutions are often the ones that click perfectly into place—just like the interlocking flooring that has revolutionized how we think about the very ground we stand on.